Whatever your motor-driven application – whether pumps and fans or compressors and mixers – it is highly likely that the installation is using more energy than it needs. There can be many reasons including:

• over-dimensioned motors

• low-efficiency motors

• variable load processes running at full speed

• poorly maintained assets

Energy Appraisal

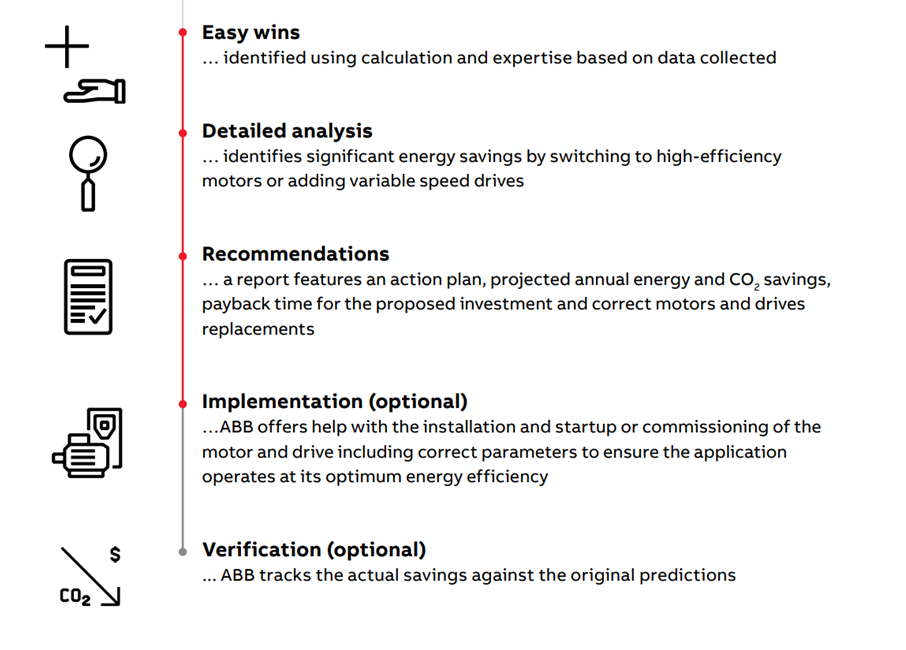

An ABB Energy Appraisal identifies the most energy wasteful motor-driven applications and recommends ways to boost efficiency and improve a facility’s sustainability. You can now select from two types of Energy Appraisals or a combination of both. They can also be included in an ABB Motion OneCare agreement.

Application-specific – aimed at motor-driven fan, pump and compressor applications without smart sensor technology. A site visit is usually required to manually collect individual asset data.

Digital Powertrain – aimed at motors fitted with ABB Ability™ Smart Sensors. Data is collected remotely and regularly from an entire fleet of digitally connected motors, allowing for regular energy use updates. A site visit can still be arranged if preferred.

Two efficient approaches – one energy saving goal

Which appraisal is right for you?

Deciding on the right ABB Energy Appraisal starts by meeting our experts who will learn about your processes and help identify those applications which may be wasting the most energy. Based on your inventory of motors and drives, the outcome determines which Energy Appraisal works best for you: the standard appraisal or the digital appraisal aimed at users embracing Smart Sensor technology.

Digital appraisal

Digital Powertrain data collection Data is automatically collected from Smart Sensors connected to assets. Smart Sensors

monitor assets regularly, allowing for more frequent energy assessments which may reveal hidden opportunities.

Standard appraisal

Application-specific data collection Data from motor and application, including load profile, site conditions, etc. is manually

collected through either a site visit or by customers forwarding the information to ABB.